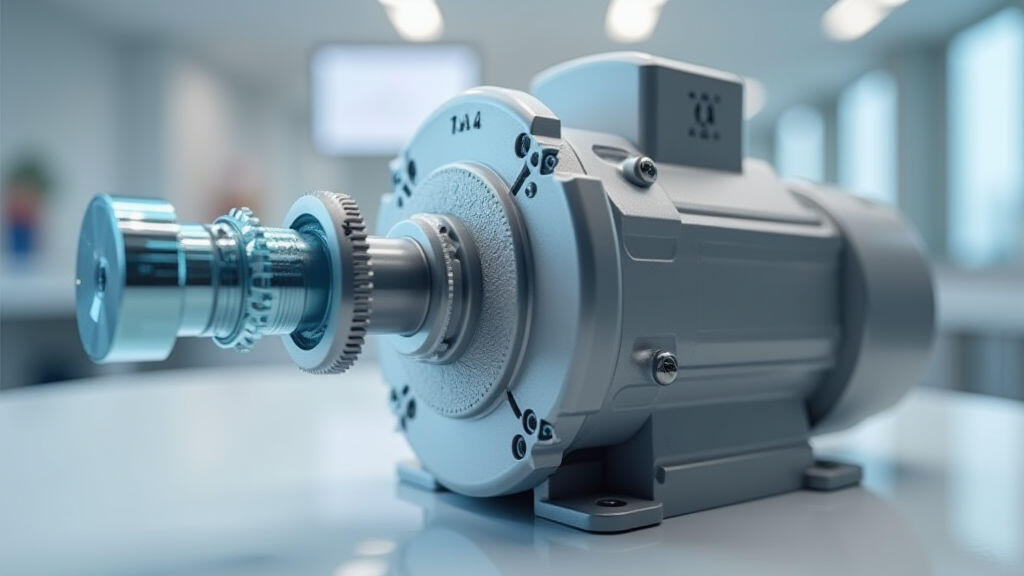

The medical equipment industry is a rapidly evolving sector, driven by innovation and the constant pursuit of improved patient care. At the heart of much of this innovation lies precision mechanics, and within that, the selection of appropriate gear motors plays a crucial role. From infusion pumps and ventilators to surgical robots and diagnostic imaging machines, gear motors provide the necessary torque, speed, and reliability. However, choosing the right gear motor isn't always straightforward. Medical equipment enterprises often fall prey to common pitfalls that can lead to performance issues, costly repairs, and even delays in product launches. This article will explore those common mistakes and offer practical solutions, especially in light of the current emphasis on cybersecurity and regulatory compliance within the healthcare industry.

Unlike industrial applications where cost might be the primary driver, medical equipment relies on stringent requirements. Accuracy, reliability, safety, and longevity are paramount. A failure in a gear motor within a life-critical device can have devastating consequences. Consider a surgical robot; a sudden motor malfunction during a procedure could have severe repercussions. Similarly, in infusion pumps, inaccurate motor performance could lead to incorrect drug dosages.

The increasing complexity of medical devices, coupled with the explosion of connected medical devices (IoMT) – a hot topic right now due to rising cybersecurity threats – puts even greater emphasis on gear motor reliability. IoMT devices are vulnerable to hacking, and compromised motors could be manipulated, potentially impacting patient safety.

Let's delve into the most prevalent mistakes medical equipment manufacturers make when selecting gear motors:

1. Overlooking Torque Requirements: This is perhaps the most common error. Often, engineers focus solely on speed and fail to thoroughly calculate the required torque. This can lead to a gear motor that’s underpowered, causing unreliable operation and premature wear. The torque requirement needs to account for not only the load but also potential variations and dynamic loads present during the device's operation. Finite Element Analysis (FEA) is a valuable tool here.

Solution: Implement a comprehensive torque calculation process. This should include load analysis, dynamic load considerations, and a safety factor to account for unforeseen circumstances. Consult with gear motor manufacturers to ensure accurate torque specifications for your specific application.

2. Neglecting Precision and Accuracy: Medical devices often demand high levels of precision. For example, a motorized valve in a diagnostic system needs to operate with pinpoint accuracy. Choosing a gear motor with low backlash or precision issues can compromise the device’s performance.

Solution: Prioritize gear motors with low backlash (less than 3 arcminutes is generally desirable for medical applications). Direct drive or harmonic drive motors are often suitable choices for applications requiring exceptional accuracy. Detailed tests and certifications (like those related to medical device standards) offer reassurance.

3. Ignoring Environmental Considerations: Medical environments can be harsh. Fluctuating temperatures, humidity, and exposure to cleaning agents are common. Using a gear motor that isn't adequately sealed or rated for the intended environment will lead to rapid degradation and failure.

Solution: Select gear motors with appropriate IP ratings (Ingress Protection) – IP67 or higher is typically recommended for medical devices. Consider materials that are resistant to chemicals and sterilization processes.

4. Underestimating Life Expectancy and Reliability: Cost is a factor, but the long-term cost of ownership is crucial. A cheaper gear motor with a short lifespan will ultimately be more expensive due to frequent replacements and downtime.

Solution: Look for gear motors from reputable manufacturers with proven track records in the medical industry. Review documentation and certifications. Ask about warranty terms and expected lifespan under typical operating conditions.

5. Cybersecurity Neglect: With the proliferation of IoMT devices, cybersecurity is no longer an afterthought. Gear motors connected to a network are potential entry points for malicious attacks.

Solution: Select gear motors with built-in cybersecurity features, such as secure boot and data encryption. Ensure that the motor’s firmware is regularly updated to address vulnerabilities. Implement network segmentation to isolate medical devices from other systems. MES-Drive offers gear motors with enhanced security protocols designed for modern medical devices.

MES-Drive is a leading supplier of high-precision gear motors specifically designed for medical equipment. We understand the critical requirements of the industry and offer a range of solutions to address the common pitfalls outlined above.

The future of gear motor selection in the medical field will be increasingly driven by factors like artificial intelligence (AI) and machine learning (ML). Predictive maintenance powered by AI can analyze motor performance data to identify potential issues before they lead to failures. Moreover, AI can be used to optimize motor control algorithms for improved efficiency and performance. The growth of personalized medicine will also demand more sophisticated and adaptable gear motor solutions.

Choosing the right gear motor for medical equipment is a critical decision with far-reaching implications. By understanding the common mistakes and implementing effective solutions, medical device manufacturers can ensure the reliability, accuracy, and safety of their products. In today's landscape, incorporating cybersecurity into gear motor selection is no longer optional – it's a necessity. As the medical industry continues to embrace advanced technologies like IoMT and AI, the demand for high-precision, secure, and reliable gear motor solutions will only intensify. MES-Drive is committed to providing the innovative gear motors that will power the future of healthcare, ensuring patient safety and advancing medical innovation.

Leave A Reply

Your email address will not be published. Required fiels are marked